A young team with a new technology are currently creating a revolution in the world of printed electronics. In their modern, brand-new lab at the High Tech Plaza, they will be developing a device that can deposit any material on any substrate at a very rapid pace. This promising technology was initially developed by TNO (the Netherlands Organisation for applied scientific research), and it is now taking off in the core of Eindhoven.

Keiron Printing Technologies’s CCO Marco van Hoorn entered the start-up life when he was a 22-year-old student in International Business. Through the Venture Building Program at HighTechXL, Marco joined start-up Aircision as an intern. It was during this experience that Marco discovered what he wanted to do: to establish his own company. And so he did.

Marco recalls with a smile: “Guus Frericks (HighTechXL Founder and CGO) told me to finish my studies before coming back. But I just walked back in and stayed.” Marco was deeply impressed by the entrepreneurial life and the amazing technologies available at HighTechXL. His enthusiasm drew Jimmy Sy-A-Chin (CEO) to connect with HighTechXL, and together with Stefan van Waalwijk van Doorn (CTO) and Prakhyat Hejmady (COO), they founded Keiron Printing Technologies in 2019.

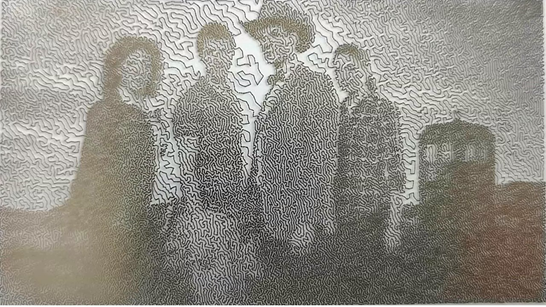

From top left corner: Jimmy Sy-A-Chin, Stefan van Waalwijk van Doorn, Prakhyat Hejmady and Marco van Hoorn.

So what exactly does Keiron do?

Keiron is a machine builder. We develop industrial equipment that enables users to deposit or lay close to any material with microscopic precision. We can deposit almost any material on any substrate, even manufacturing layers of different materials on top of each other and at different height. This means that the technology enables complex functionalities to be added to chips during the production process.

Keiron concept

We utilize a superior direct-write technology. Because a laser is employed, the process is very controlled. For example, this technology enables printing circuits so fast that it’s just impossible to capture it with a camera. This means that in 0.07 seconds we can get a whole circuit printed, and that’s impossible with today’s nozzle-based technology.

This technology is quite relevant for microfluidics (the science and manipulation of fluids). For example, think about adding microelectronics in chips that carry samples of blood or other body substances or printing sensitive biological materials like cells. This would only be one of the applications. Keiron is currently focused on diversifying and looking for the overlap of applications with the microfluidics such as semiconductors, semiconductors packaging and biosensors. All in all, this is a technology that provides opportunities for the mass production of flexible electronics.

Microfluidic chips with electrodes

How does direct-write compare to current printing technologies?

Current printing technologies are very slow, and direct-write technology enables a whole new world of possibilities. With a laser, printed materials keep their shape and adhere better to the surface, which is a big advantage. The speed it offers is also incredible. For example, with today’s technology one can print a half a meter line per second, but with direct-write technology one can print 9 or 10 meters per second (20 times faster). This has a huge potential for mass production. The technology also enables reaching tiny feature sizes, -a lot smaller than the size of a human hair.

Direct-write laser printing made by TNO Holst Centre

What’s the ultimate goal of Keiron?

We want to be the leader of printed electronics, just like ASML is the world’s largest supplier of photolithography systems in the semiconductor industry. The device we’re building will be the enabler for a great variety and number of printed electronics applications. Our first idea is to sell the machine and make profit, but once we have the capital, we’d like to install machines at the customer’s location in which the client pays per use. In the long term, this may be more profitable for the company.

As a company, we also have a responsibility of contributing to a better and more sustainable world. We know that additive techniques in manufacturing are becoming more eco-friendly, and we want to be part of this movement! As a member of the supply chain, our machine will be able to make products that will improve our lives. For example, a chip that can make a quick health diagnosis or register the amount of CO2 in the atmosphere. We strive to make an impact and support those companies that develop technologies for the future. This means that in five or ten years Keiron will be there to supply all major companies with the right machinery.

Machine making chips

What’s life like as a young entrepreneur?

“It’s very fun!” We learn new stuff all the time, but we’re young and learn quick. We basically had to become experts in a short period of time but since we’re a very young team, we also rely on the advise of our board. We are very grateful to have in our team Richard Visser (Founder of Smart Photonics), Helen Kardan (Sr. Account Manager at ASML), Eddy Allefs (CTO at HighTechXL and D&E Innovation Consultant at NTS-Group) and Ton van Mol (Director Flexible and Free form electronics at TNO Holst Centre). They have tons of experience and help us making important decisions. They’re part of the Keiron family.

Sometimes age can also be a disadvantage when you’re an entrepreneur. We engage in meetings with possible customers that are easily 20 years older than us, and it can be a challenge. They might doubt our experience or our commitment to the company. However, many times people are impressed with our achievements so far despite being so young.

What have been the biggest achievements and challenges so far?

Well, we already discussed our age being a challenge during meetings. Finding investors is a challenge for any start-up. A particular situation that we face is introducing a new technology to the manufacturing industry. The technologies used right now are very well known, so introducing a new concept and winning people’s trust is a big one. We need to demonstrate that we have something reliable and viable. That’s one of the issues when we talk to people with tons of experience, but they’ve never heard about this technology. People are not familiar with the idea that a laser can print something, so it’s quite a surprise for them.

On the other hand, we’re now in conversation with one of the largest manufacturers in Europe that is really excited with what we offer. It’s just a huge validation for our team when this company says: “I want this technology, I want this machine in my foundry. It’ll be part of the whole manufacturing process of the chip.” We also just got approved for two subsidies, so this is also a huge achievement and confirmation that we’re on the right path. This means that people see what we see and believe what we believe.

Keiron just opened its first office at the High Tech Plaza; why did you decide to stay here?

This region is great for our company. If we’re going to be making parts for chips, it makes sense that we stay in Eindhoven. Integrating a laser-based printing process machine that can be used in the industry is not an easy project. There are lots of implications in the process, people have a lot of questions, they face challenges in the technical point of view, etc. But this region has the expertise and entrepreneurial spirit to help us out. If Eindhoven can’t do it, there’s no other place else that can do it.

The Eindhoven mentality is the reason why startups have grown in the region. It’s very easy to sit down and help others just for the sake of helping. Moreover, the network is available, which is very inspiring; there are people willing to help in the thinking process and give back to the community.

Lastly, do you have any advice for any new startups or people who want to start a company?

The number one advice is to not be afraid to make mistakes, and the sooner you make them the better. People are really scared to not look smart. They just want to be right all the time. This hinders learning and development, which is crucial for developing a company.

And it’s also very important to have lots of courage. Don’t let people’s opinions bring you down because you might have discovered a new way of doing something. So, always remember that the new way of thinking can be the right way of thinking and that, at some point, everything was new.

Would you like to know more about Keiron Printing Technologies? Email them at: info@keirontechnologies.com